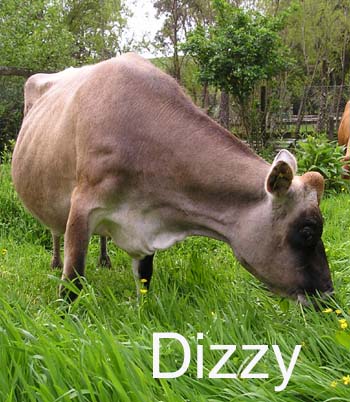

I’ve been a bit negligent on this site recently but I thought you’d enjoy this picture of our senior cow Dizzy, (who I have to say is not), she’s a very staid middle aged cow, but her pedigree name given by her former owners is Braidwood Disney Aura, which is a bit of a mouthful to shout out in the paddock, & she seems to be quite happy being called Dizzy. She’s having a lactation rest at the moment while she is gestating. She, and her daughter Lily, who is expecting her first calf, should be welcoming their calves at the end of October when the paddocks in NZ should be green with spring growth.

There has been quite a bit of correspondence with MPI over my application for a ‘Significant Amendment’ to my RMP so I can make raw hard cheese to sell and I think things are progressing. I’ve sent them various HACCP charts on my milking and cheese making processes, for which I have to thank Dr Paul Neaves, a food microbiologist in the UK, for putting my long winded explanations into wonderful one page documents. Another reason for my lack of posts is that I wrote quite a long one, but ran out of day to finish it and the next day, when I went to finish editing it, I discovered it had disappeared into computer ether, which was annoying. Never mind, that’s life, I suppose.

I was looking though the nether regions of my rather chaotic desk and discovered this piece I wrote in 1994, a year before we moved here to Cwmglyn Farm. It has nothing to do with cheesemaking or HACCP documents and was a writing execise whereby you had to write a piece incorporating the phrases ‘A spade upright in the soil’, ‘A stale loaf of bread’ and ‘Riding into the Sunset’. It was fun to write and I used an incident in my own family lore concerning my Great Grandmother and her sister. I’ve given everyone fictional names… Here goes….

“Jealousy is such a destructive emotion” said the old lady looking reflectively into the flames and poking the rather pathetic sticks to increase the blaze. We were having tea, one cold winter afternoon in her old fashioned front room. I, doing my monthly visit and feeling guilty that I should regard the little time I spent with her as a duty rather than a pleasure. I didn’t care to dwell too much on what she did on her other days -I suspect they were mostly spent alone -her remark, “the worst thing about longevity, my dear, is that one outlives all ones friends” was made with so much acceptance that I was suddenly afraid of the time when I, too, would be old and alone. Would I have her fortitude to accept such solitude or the painful signs of incipient poverty I’d seen in her small kitchen? She’d caught my intrusive glance at the stale loaf of bread in the open bread bin, as I helped her prepare a tray for afternoon tea. Her courageous “I’m saving that to make bread and butter pudding” displayed her spirit.

“Do you know, I haven’t had that for years” I said, to cover my confusion, “Martin always insists on wholemeal bread and it isn’t the same made with that.” We smiled at one another, acknowledging the small social skirmish gracefully executed as we made out way back to the front room. And now I smiled again and leaned back into my chair to enjoy another tale of family feuds and doings from her past.

“My Aunt Mary’s life was entirely ruined by her jealousy of Catherine. Sibling rivalry, I suppose you’d call it now.” My Great Aunt Helen kept herself remarkably well informed where jargon was concerned. I suspected her hours were often spent watching educational television programmes. “Catherine was a couple of years younger than Mary and a real beauty. Poor Mary had inherited the unfortunate Wilkes nose and had ginger frizzy hair that defied every effort of setting it into a fashionable style. She tried everything ever recommended in the woman’s magazines and a good deal else in desperation. But nothing worked.”

Unconsciously she patted her own smooth silver hair, looped gracefully from a center parting, covering her ears and knotted neatly behind. She was still a very handsome woman despite her wrinkled face and papery skin. “Mary, I’m afraid, was distressingly plain with a fearsome temper and was terrified of being left on the shelf. In those days, my dear, unmarried daughters in our family were expected to remain at home. Running off to get themselves educated or train for a career was not considered the thing, even if they were still unattached at the end of their second season. And poor Mary had had to endure the indignity of a third. Her parents, who were possibly considered a little old fashioned even then, assumed that their friends would think they hadn’t the means to support them if any of their girls embraced a career. So Mary had to suffer the humiliation of watching her pretty younger sister entertain and discard suitors by the dozen. I’m afraid she became very bitter. Can I persuade you to have another cup. my dear?”

Great Aunt Helen took my cup, emptied the contents into the slop basin and filled its silly fluted sides with more tea. I knew the liquid would be cold within minutes and wished she’d use her ordinary cups on my visits. They, at least, kept the tea hot.

“Had she no interests or activities to divert her?”

“None. Indeed had she some suitable occupation I dare say she wouldn’t have reacted as she did……Well, of course, the day came when Catherine became engaged. An American, but a lovely man for all that. He was very comfortably off, but his name! Sometimes I wonder where these Americans dream them up. Riding I.T.T. Sunset – I don’t like to think what the initials stood for nor what his parents were thinking to name their only son thus.” She shook her head and sighed, “But Americans are very strange, although very kind, I understand. And Riding was the kindest man. I remember the wedding day very clearly -it was to be such a splendid day.” She paused to remember a day some seventy years before. “No expense was spared for the wedding. I was about 10 years old and to be a flower girl. I was so proud of my pretty dress with it’s blue satin sash and matching silk slippers. A big marquee had been set up on the lawn. The servants were up before dawn arranging everything to be just so. Henricks, the butler, had engaged extra staff, professional florists came in to decorate the church -and I can’t tell you what a rumpus that caused with the ladies who normally did the flowers at St. Michael’s. Mary was a bridesmaid and none too happy about that -as the older sister, she expected to be married first. In fact she had quite a tantrum when the engagement was announced because she said that Catherine ought to wait for her to be married first. But we all thought it had been smoothed over. And then, about two hours before the ceremony, Mary disappeared.

We hunted high and low for her, but nobody had seen her. Servants were dispatched to help in the search, family and wedding guests all roped in. My mother and Cousin Hetty, both disposed to having the vapours, vied with each other over possession of the smelling salts. Then one of the extra servants mentioned he’d seen a young lady dressed as a bridesmaid walking towards the river. He was bidden to join in the search. Riding, too, having had word there was some sort of upset at the house had come to offer assistance. So he joined in the search and it was he who found Mary’s clothes -her beautiful bridesmaid’s dress neatly folded by the river with her shoes on top and the lace parasol, furled by the side. Bare footprints were discovered at the river’s edge.”

“Goodness how terrible. What an awful shock. Whatever happened?”

“Of course the ceremony had to be cancelled, even at that late stage. Men were summoned from the village to help drag the river. Oh there was a terrible to-do. Guests had to be told and turned away and I saw Catherine sobbing her heart out in her room. I’d never seen a grown-up cry before. ‘I knew Mary meant to ruin my wedding, she’s a wicked, wicked person. I don’t think she’s drowned at all, she’s just done this out of spite. I know she has, it would be just like her’ “.

Great Aunt Helen took another drink of tea, replaced her cup and patted her lips dry with a small embroidered napkin. “Catherine was quite right, of course. Mary had indeed faked her ‘suicide’. She had obviously put some other clothes ready under a bush, walked down to the river’s edge in her bridesmaid’s gown, after making sure someone had seen her. She changed her frock, folded the other and carefully made her footprints in the mud. I presume she paddled along the riverbed until she could scramble out without leaving any tracks. She walked the five miles to Godalming and then took a train to Guildford. Alfred Tuttlebridge met her there by arrangement and she married him by Special Licence that day. They took a train to Folkestone and spent their honeymoon at the Clifton Hotel. Once the marriage was consummated, she sent a telegram home to the family telling them to stop looking for her corpse”.

“What an extraordinary story. I’m amazed that I never heard a whiff of it whispered in the family”.

“I think they were all too embarrassed about it, if the truth be told. Alfred Tuttlebridge wasn’t considered much of a catch and it was presumed that Mary only married him because he was fool enough to be manipulated by her. She was quite determined, you see, that she was to be married first and she knew she hadn’t a chance of making her nuptials more interesting than Catherine’s. I think that had Mr Tuttlebridge offered for her in the normal way, Mary or the family would have turned him down”. She turned and smiled at me, “he was always very kind to me. But Mary could induce him to do anything she wanted. I’m sure he had no idea at the time how his bride had wrecked her sister’s big day”

“And Catherine?”

Well Catherine and Riding’s marriage took place soon after Mary’s wire. It was a very happy day, despite Mary’s outrageous behaviour being the most talked about subject at the wedding. I’m sure that Catherine and Riding had more happiness in the few days left to them than ever Mary had in her years with Alfred. As you know, Catherine and Riding were drowned on their honeymoon voyage on the Titanic. And your grandfather Tuttlebridge died, too, later in the Great War. Killed, so we were informed, as he put his hand to a spade upright in the ground as he was digging in the trenches, poor man. I don’t think he ever knew much happiness.”

“From what I’ve heard, I don’t think my grandmother was ever a woman to engender it” I said. I only knew her from her embittered face, severe and trapped in a sepia photograph at home in the family album. She died when I was quite young.

I looked regretfully at the clock and realised that I would have to leave were I to catch my train in time. I stood up and kissed my Great Aunt. “I’ll see you soon,” I said, “don’t get up, I’ll see myself out.”

She smiled, dismissing me and settled back to her memories.

Copyright 1994 Biddy Fraser-Davies.

There you are, nothing about HACCP at all!